Digitalisation & Pharmaceutical World

The pharmaceutical manufacturing industry is growing drastically due to the increasing demand for its service. Digitalization can embrace almost all spheres of pharma industry, especially manufacturing. Let us see how!

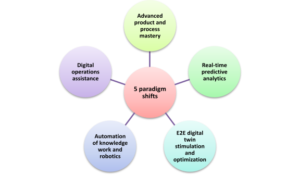

Five Paradigm Shifts in Pharmaceutical industry:

A comprehensive approach is necessary because of five fundamental shifts in how the pharmaceutical industry will be shaped in the coming years. These five paradigm shifts are as follows:

- Minimizing Variations: Pharmaceutical companies can run historical data on Chemistry, Manufacturing, and Control (CMC) by building an advanced analytical model to determine the impact of individual changes. Pharmaceutical companies can use modern and new technologies to understand better how input parameters such as operator training levels, raw materials options, and machine settings will affect the quality of products and outcomes. To eliminate testing and cut throughput times in half, companies can control over input parameters to regulators. This automatically boosts efficiencies, as most of the quality control and quality assurance tasks disappear. Also, by mapping outputs to inputs, companies can proactively optimize all inputs and thus reduce variations.

- Real-time data to map market trends: Internal and external indicators, big data, and machine learning algorithms can be leveraged by the industry stakeholders to forecast trends and automatically identify and mitigate risks such as quality issues, deviations, and machine failures, etc.

- Digital optimization: The real-time digital twin stimulation allows companies to steer the process presciently by assuming the effect of adding a new machine, changing the team allocation, or changing schedules. This can help the company optimize production parameters for a highly complex system, proactively and accurately, without risk. Companies can also build digital stimulation of production processes on individual machines, factories, labs, or the entire manufacturing network. This is a significant advancement in efficiency compared to the traditional approach of going through historical data manually to spot trends.

Fig 1.1 Five Data Driven Paradigm Shifts in Pharmaceutical industry

- Automation through robotics: Digital robots can autonomously handle supply scheduling and planning measures, using self-learning algorithms to support decisions such as corrective and preventive actions (CAPA) or portfolio margin optimization. Such tools are emerging to improve knowledge work, automation, and administrative processes. Suppose there is any deviation in a product. In that case, natural language processing can be used, which can help to show where and what went wrong and compile it into a Pareto diagram or some other type of visualization. All these solutions can reduce the company’s time by 10% but by 90-100%.

- Reducing human errors: Human error is the biggest weakness in pharma production. Tasks done by humans are almost 92% accurate statistically. This does not comply with pharma expectations. Therefore, new digital systems that support operators in daily tasks highly repetitive have a massive increase in the pharma industry. These tools can let managers know if something is going wrong or is likely to go wrong.

Future prospect: Digital manufacturing in pharma is the industry’s new reality. Leading companies can develop a roadmap to implement and capture substantial gain in production capacity by 40% and reducing unit costs by 15%. The companies can embrace innovation and position themselves to compete in a future that will look very different from today.

References:

- https://www.epicflow.com/blog/2020-challenges-and-trends-in-pharmaceutical-industry/

- https://www.mckinsey.com/business-functions/operations/our-insights/how-data-is-changing-the-pharma-operations-world#